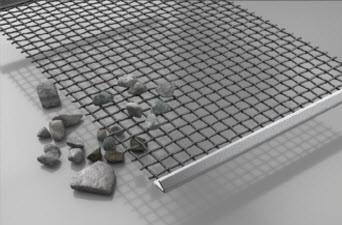

Non-Clog Flex Screens for sieving systems

Non-Clog Flex Screens for use in sieving systems has been developed to prevent blockages in the bottom layer of the sieve machineIt is manufactured with flat knitting and polyurethane support that prevents clogging. It is recommended to use a minimum hole diameter, and efficiency decreases as the hole diameter gets larger.

Clogging points do not occur due to clogging. There is no need to clean the clogged surface.

Flex Non-Clog Screens are used to sift fine-grained materials with particles that tend to stick. It is made of corrugated or flat, wire or Polyurethane material at certain intervals. It is based on the principle that the strings are springing and a stretched string vibrates easily. It can be installed as with normal square hole sieve tissue.

Why doesn't it clog?

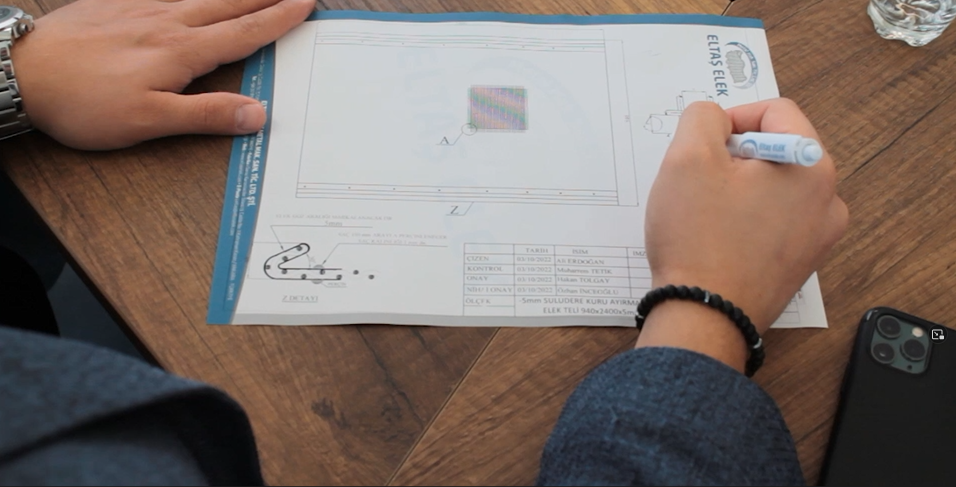

The problem of clogging, which is a problem in sieving systems, has been solved with such sieve wires. The reason is; The reason is that the wires between the two support plates that work independently of each other do not hold the material at the moment of vibration. As it is not washed, it provides capacity increase.

The horizontal position of the wire used, the fact that the stone does not touch the top of the normal sieves and does not erode one point, extends the life of the sieve wire. According to the silica state of the aggregate, the life of the sieve wire is between 8 -18 months, depending on the stretching state. In addition, the fact that the distance between two blades is not more than 250 mm extends the life of the sieve wire.zla olmaması elek telinin ömrünü uzatmaktadır.

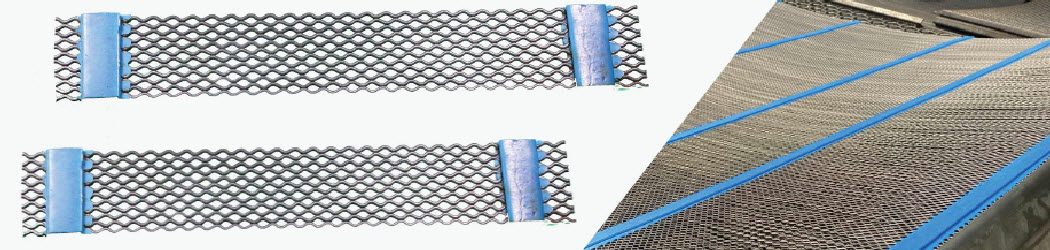

Advantages over Steel Mesh Screens

According to steel mesh screens;

- Surface opening (number of holes) is high.

- Long-lasting,

- 30% more efficient

- Does not create clogging while sieving muddy material

- Eliminates the time wasted for cleaning clogged areas

Other Features

• It completely eliminates blind spots caused by clogging.

• Screening surface is 30% more than steel mesh screens.

• In addition, Steel sieve has a longer life than traditional mesh sieves.

• Time spent cleaning clogged surfaces disappears.

• Specially designed and manufactured for Asphalt Plants.

• Steel sieve provides high performance with its specially designed wire combination.

• It is preferred in asphalt plants as it is heat resistant.

• Production is made in desired mesh openings and dimensions.